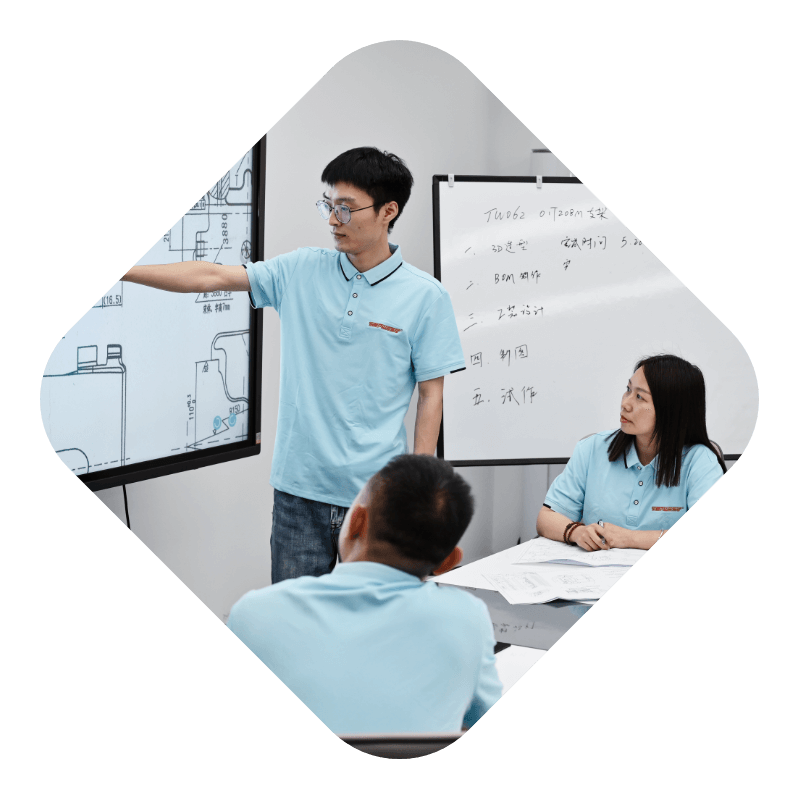

需求分析和规划阶段:

与客户进行沟通,了解其需求,目标和预期;

确定产品的基本功能,特性和规格;

确认量产计划和时间表;

进行市场调研,分析竞争对手和市场趋势。

Requirements Analysis & Planning:

Initial requirements gathering from customers;

Determine the basic functions, characteristics, and specifications of the product;

Making mass production plan and schedule;

Doing market research, analyze competitors and market trends.

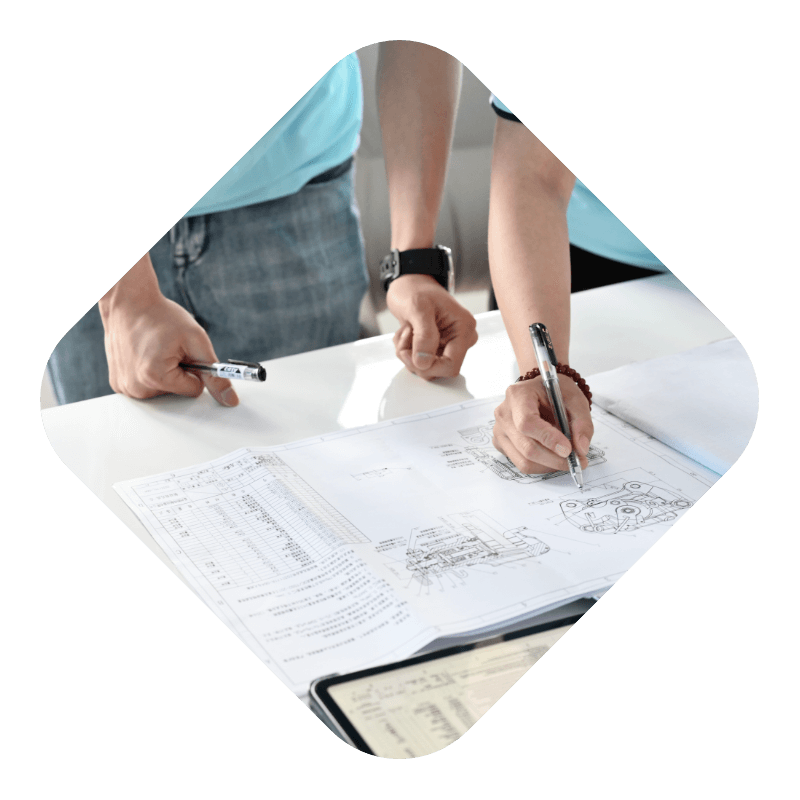

原型设计和开发阶段:

制定产品的初始设计方案;

进行设计验证和评估,并与客户进行沟通和反馈;

修正和调整设计,进一步优化产品性能和外观;

制作样品并进行测试和验证。

Prototype Design and Development:

Making the initial design product plan;

Doing design validation, evaluation, and communicate with customers;

Revise and adjust the design to further optimize product performance and appearance;

Make samples and conduct testing and verification.

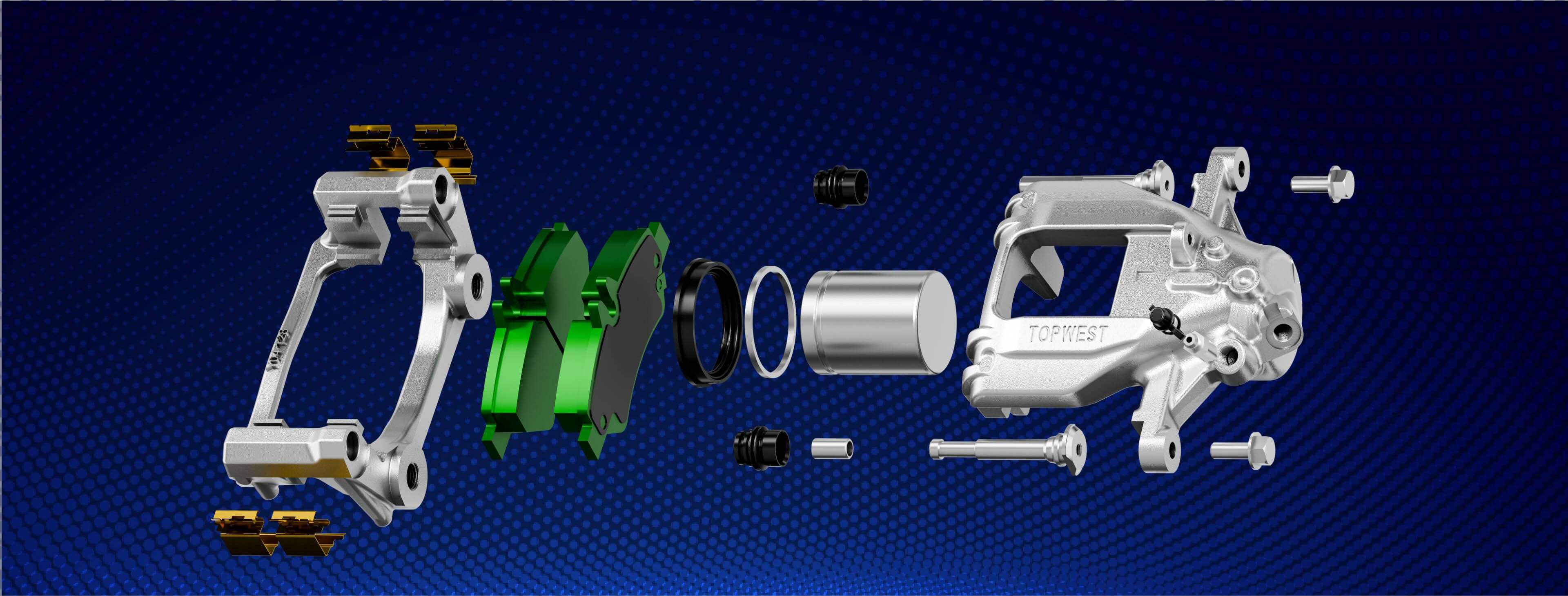

工程设计和开发阶段:

根据经过验证的设计方案进行详细设计;

开发和优化产品的机械和软件;

进行原材料的选型和采购。

Engineering Design and Development:

Conduct detailed design based on validated design schemes;

Develop and optimize product machinery, and software;

Selection and procurement of raw materials.

售后服务和反馈阶段:

提供产品的售后服务和技术支持;

收集客户对产品的反馈和意见;

对产品进行改进和优化;

发展长期的合作伙伴关系。

After Sales Service and Feedback:

Provide after-sales service and technical support;

Collect customer feedback and opinions for the product;

Improve and optimize the product;

Developing long-term partnerships.

量产和交付阶段:

进行大规模的批量生产,确保产品质量和一致性;

设立质量控制和检测流程;

开展生产现场培训和操作指导;

确保按时交付产品,并提供售后支持。

Mass Production and Delivery :

Conduct large-scale mass production, ensure product quality and consistency;

Establish quality control and testing processes;

Conduct on-site training and operation guidance for production;

Ensure timely delivery of products and provide after-sales support;

制造和试产阶段:

安排原材料供应商,确保供应链的可靠性和质量;

完成产品的小批量试制;

进行供应评估和流程优化;

测试和验证制造流程和设备。

Manufacturing and Trial Production:

Arrange raw material and ensure the reliability and quality of the supply chain;

Complete small-scale trial production of the product;

Conduct supply assessment and process optimization;

Test and validate manufacturing processes and equipment.